Bushfire's team is super helpful. Great product. Highly recommend!

- Noah

Whether you’re preparing for fire season, managing water around your property, or looking for the right pump for spraying, choosing the right pump can feel overwhelming. This guide for fire water and spray pumps breaks down the key differences between various pumps, so you can confidently select the one that suits your needs.

Specifically designed for high-pressure applications, these fire pumps are essential for protecting homes, properties, and farms from bushfires. Their ability to push water over long distances and up slopes makes them ideal for fire defense, especially in rural or high-risk areas.

1. High Pressure: Firefighting pumps are built to deliver significantly higher pressure than other pump types. This pressure enables water to reach rooftops, tree canopies, or areas far from the pump’s location, crucial during emergencies when accuracy and reach matter most.

2. Engine Types: Most firefighting pumps come with petrol engines due to their availability and lighter weight, making them easy to carry or mount on UTVs or trailers. Diesel engine options are also available, often preferred for their fuel efficiency, longevity, and safer storage in hot conditions.

3. Start Mechanisms:

Designed to move large volumes of water quickly, these pumps are perfect for transferring water between tanks, dams, troughs, or reservoirs. They prioritize flow rate over pressure, making them ideal for general water relocation on farms or properties.

1. High Flow Rate: Water transfer pumps are built to move a large amount of water per minute. This makes them efficient for tasks like emptying a water tank or filling up a livestock trough.

2. Lower Pressure: Unlike firefighting pumps, these pumps operate at lower pressure because the focus is not on distance or height but on volume. They’re best used where you need a strong, steady flow close to the pump.

3. Engine Types: Typically powered by petrol engines, making them portable and easy to operate in areas without mains electricity. Some larger models are available in diesel for improved fuel economy and extended use.

4. Lightweight & Versatile: Most models are lightweight and come with handles or frames, making them easy to carry and set up wherever needed.

Used for agricultural or weed control applications, spraying pumps deliver measured volumes of chemical or water-based sprays through nozzles. Commonly used for crops, fence lines, spot spraying, or pasture management.

1. Consistent Medium Pressure: Spraying pumps need to deliver a consistent pressure to ensure even coverage of herbicides, pesticides, or fertilizers. Too low and the spray won’t reach; too high and you risk over-application or drift.

2. Chemical-Resistant Components: Look for pumps with Viton seals or UV-stabilized poly components, which are resistant to harsh chemicals and prevent premature wear and leaks.

3. Power Options

4. Compatibility with Spray Equipment: Spraying pumps often come integrated with booms, hoses, and reels or are sold to fit with UTV/ATV tanks and trailers. Matching flow rate and pressure with your spray equipment is crucial.

Built to safely and efficiently transfer diesel fuel from storage tanks to vehicles or machinery. These pumps are widely used in farming, construction, and transport industries.

1. Built for Diesel Use: Diesel transfer pumps use chemical-resistant seals and materials like Viton or Nitrile, ensuring safe, leak-free operation with flammable fuels.

2. Low to Medium Pressure: Because the focus is on controlled delivery rather than speed or reach, these pumps operate at lower pressures, often measured in L/min instead of PSI.

3. Power Options

4. Integrated Flow Meters & Nozzles: Many diesel pumps come with auto-shutoff nozzles, in-line filters, and digital flow meters to ensure accuracy, safety, and compliance.

Choosing the right pump can be overwhelming with so many types and features on the market. Whether you’re tackling fires, transferring water, spraying crops, or moving diesel, keeping the following key factors in mind will help you make a confident decision.

Start by identifying what you’ll use the pump for most often.

Not all pumps are built the same.

The inlet and outlet size affects how quickly water flows through the pump and determines which hoses and fittings will be compatible.

Depending on how and where you’ll use your pump:

When handling herbicides, diesel, or other chemicals, ensure the pump is made from the right materials:

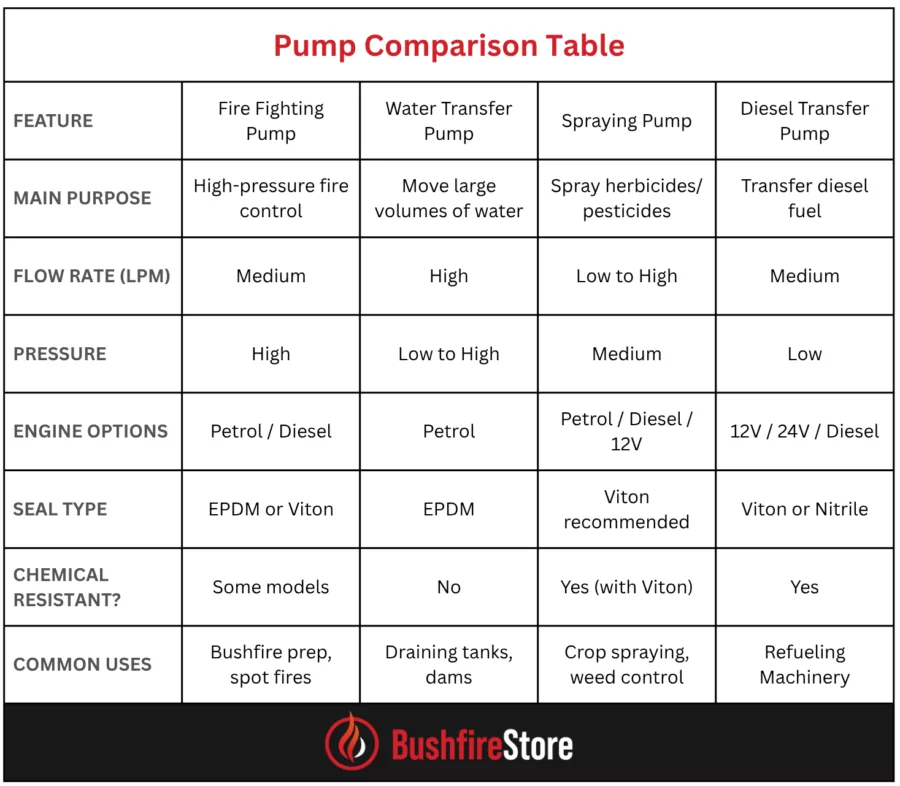

Not sure which pump suits your needs best? This quick comparison table, a visual representations of the guide for fire water and spray pumps, breaks down the key differences between firefighting, water transfer, diesel, and spraying pumps to help you make a confident choice.

Check out the video here for a helpful visual explanation of how different pumps work.

Choosing the right pump doesn’t have to be confusing. With this guide, you’re better equipped to select the pump that fits your task—whether it’s spraying, transferring diesel, or preparing for bushfire season.

Need help? Contact our team at Bushfire Store and we’ll guide you to the right product.

Bushfire's team is super helpful. Great product. Highly recommend!

- Noah

Really great service and product knowledge. Took the time to explain in detail about the products and advised on the perfect item for my complicated enquiry. Had a good chat and made me laugh too. Thanks

- Ali Ross